Tubing conveyed sand pump

Special Features Add Safety and Performance |

|

| Screen Sub: | Small slots in sub allows fluid to reenter annulus but not sand and junk cuttings which could possibly settle and stick the pipe in the hole. |

| Double Action Piston: | Pumps fluid on both upstroke and downstroke of the piston. Full open bore thru piston and kelly prevents sand etc. from fouling the piston. |

| Fluid Mixing Port: | Allows clean off bottom fluid to mix with sand laden fluids in the pump and makes piston more resistant to plugging. |

APPLICABLE TO ALMOST ALL CLEAN-OUT AND FISHING

OPERATIONS IN LOW FLUID LEVELS AND SHALLOW WELLS:

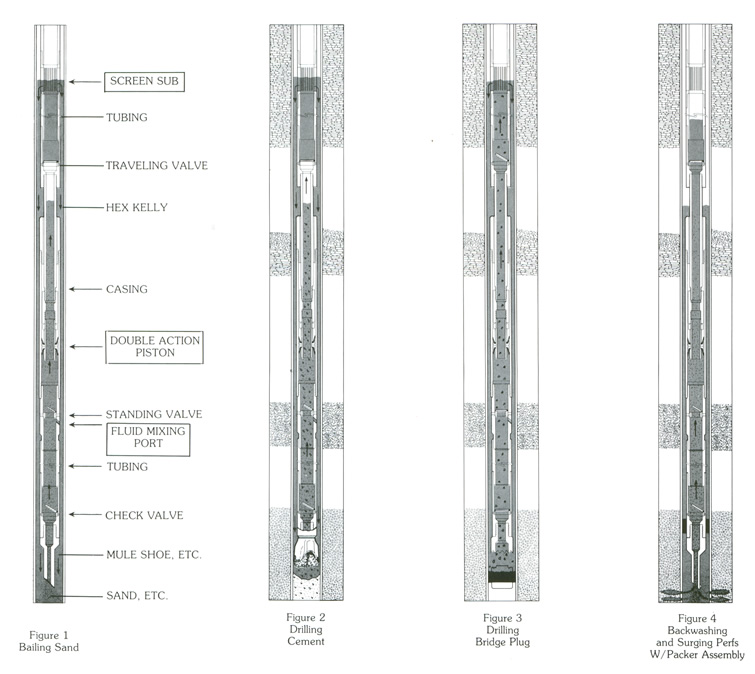

- Bailing sand, scale, and debris

- Bailing frac sand and retrieving bridge plugs in one trip

- Drilling out cast iron bridge plugs

- Drilling out cement and cement retainers

- Milling packers and miscellaneous junk

- Fishing loose junk

- Backwashing and surging perfs

- Reverse circulating debris off bottom

ALL CAN BE ACCOMPLISHED WITHOUT THE NEED FOR REVERSE CIRCULATION EQUIPMENT OR LOADING YOUR WELL WITH FLUID!

OPERATION

The Model DA Tubing Pump may be run on tubing or drill pipe. The tool's hexagonal Kelly transmits surface rotation of the pipe to the lower end of the pipe whenever rotation or drilling is required. The Tubing Pump is designed to clean out sandfill, junk, or any other loose debris from a well with fluid levels too low to permit using a Cavins Hydrostatic Tubing Bailer or Junk Snatcher. The Tubing Pump is actuated by reciprocating the pipe. On the upstroke of the piston, fluid and debris is vigorously pulled from the well into the lower end of the pipe and retained by the check valve. On the downstroke of the piston, fluid and debris within the pump barrel is pumped upward through the full open passage in the Kelly into the tubing above the pump. Fluid reenters the annulus through the screen sub or a ported sub located above the pump in the pipe. If circulation of a well is impossible due to sandfill above the perfs, the screen or ported sub may be omitted to allow reverse circulation of the well through the Tubing Pump's full open passages until the perfs are uncovered and fluid returns are lost. The double action design of the piston, the unobstructed passage through the Kelly, and the fluid mixing port greatly reduce the probability of sand or other debris clogging the pump and interfering with the pump's operation until all cleanout operations are completed.

SPECIAL FEATURES ADD SAFETY AND PERFORMANCE

SCREEN SUB: Small slots in sub allow fluid to reenter annulus but not sand and junk cuttings, which could possibly settle and stick the pipe in the hole.

DOUBLE-ACTION PISTON: Pumps fluid on both upstroke and downstroke of the piston. Full open bore through piston and Kelly prevents sand, etc. from fouling the piston.

FLUID MIXING PORT: Allows clean-off bottom fluid to mix with sand-laden fluids in the pump and makes piston more resistant to plugging.

MULTIPLE APPLICATIONS

By substituting a mill, bit, burning shoe, retrieving tool, etc. to the bottom of the work string, the Model DA Tubing Pump may be utilized in various cleanout, drilling, and fishing applications.